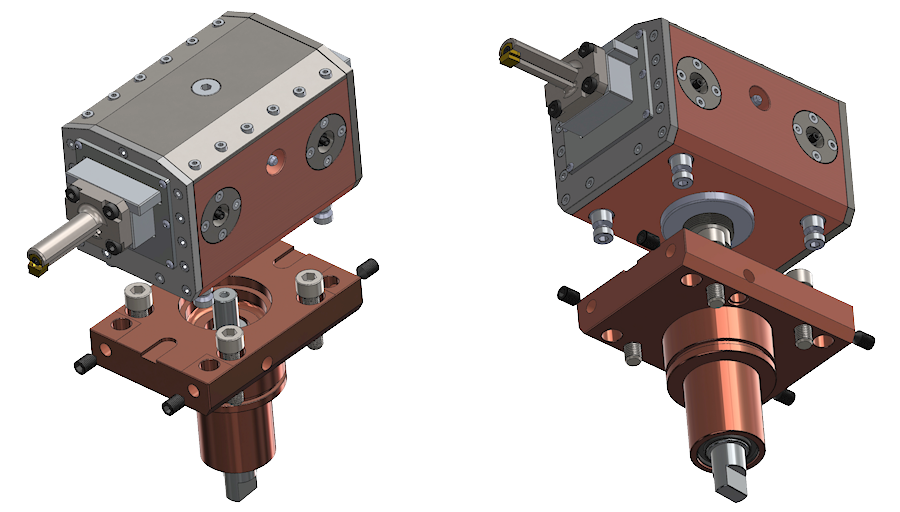

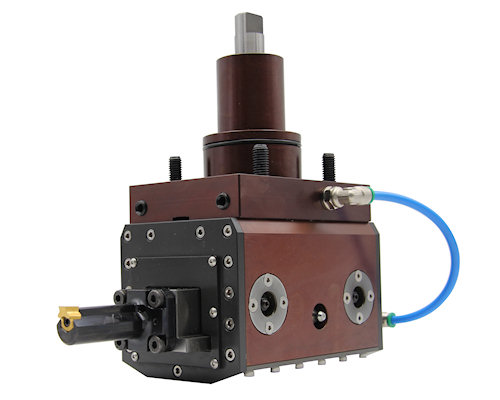

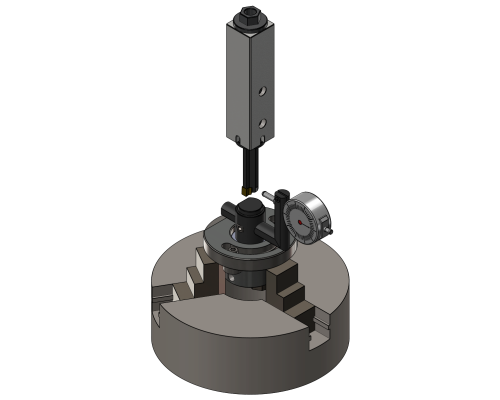

Il sistema REV Broaching Tool è una soluzione intelligente ed efficace che permette di realizzare sedi di chiavetta e stozzature direttamente su torni CNC e centri di lavoro, senza dover attrezzare altre macchine e senza doversi rivolgere a specialisti esterni. Questo garantendo lavorazioni con un'ottima finitura e sempre perfettamente in tolleranza. Il REV Broaching Tool, inoltre, impiegato su stozzatrici e limatrici, rappresenta una valida alternativa agli utensili tradizionali distinguendosi per versatilità e robustezza. Il sistema REV è l'unico che mette a disposizione del cliente i programmi completi per l'utilizzo su CNC e che segue tecnicamente il cliente in ogni sua esigenza, senza alcun costo aggiuntivo.